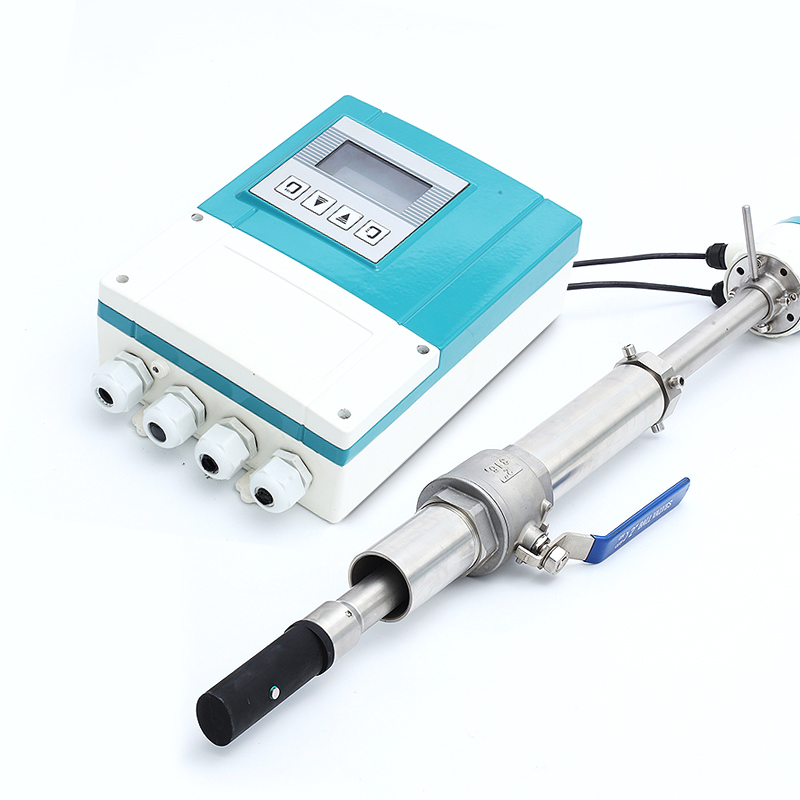

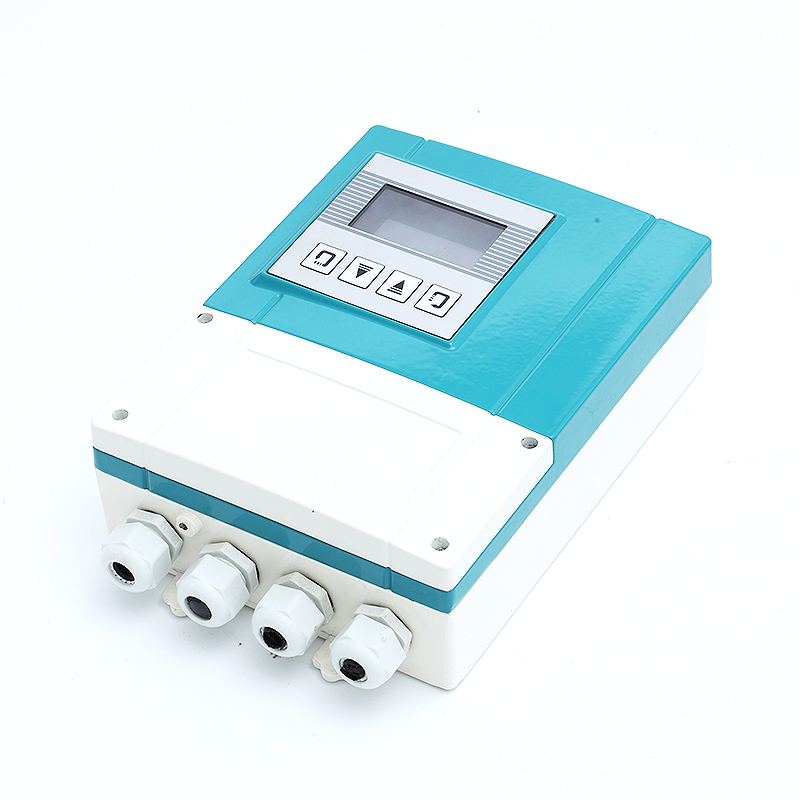

Ηλεκτρομαγνητικό ροόμετρο τύπου split

Ηλεκτρομαγνητικό ροόμετρο τύπου split

- Υψηλή ακρίβεια και σταθερότητα: Το διαιρούμενο ηλεκτρομαγνητικό ροόμετρο υιοθετεί ακριβή σχεδιασμό αισθητήρα και τεχνολογία επεξεργασίας ψηφιακών σημάτων για να διασφαλίσει τη σταθερότητα της ακρίβειας μέτρησης.

- Ευρεία προσαρμοστικότητα: Κατάλληλο για μέτρηση ροής διαφορετικών υγρών μέσων, συμπεριλαμβανομένων νερού, λυμάτων, λάσπης, πολτού, διαφόρων οξέων, αλκαλίων, διαλυμάτων αλάτων κ.λπ.

- Ισχυρή αντιδιαβρωτική απόδοση: Οι επενδύσεις και τα ηλεκτρόδια με διαφορετικά υλικά μπορούν να αντισταθούν στη διάβρωση από διάφορα διαβρωτικά υγρά.

- Εύκολη εγκατάσταση: Ο αισθητήρας και ο μετατροπέας εγκαθίστανται χωριστά, γεγονός που μειώνει την επίδραση στη δομή του αγωγού και είναι κατάλληλο για ανάγκες μέτρησης ροής διαφορετικών ροών διεργασίας.

- Χαμηλό κόστος συντήρησης: Ο διαχωρισμένος σχεδιασμός διευκολύνει τη συντήρηση και την ενημέρωση του οργάνου και μειώνει το κόστος συντήρησης.

Επισκόπηση προϊόντος:

Αρχή μέτρησης: Το διαιρούμενο ηλεκτρομαγνητικό ροόμετρο λειτουργεί βάσει του νόμου του Faraday για την ηλεκτρομαγνητική επαγωγή. Όταν ένα αγώγιμο υγρό διέρχεται από ένα μαγνητικό πεδίο, θα προκαλέσει μια επαγόμενη ηλεκτροκινητική δύναμη στην κατεύθυνση κάθετη στο μαγνητικό πεδίο. Μετρώντας το μέγεθος αυτής της επαγόμενης ηλεκτροκινητικής δύναμης, μπορεί να υπολογιστεί ο ρυθμός ροής του αγώγιμου υγρού. Το ηλεκτρομαγνητικό ροόμετρο δημιουργεί ένα ισχυρό μαγνητικό πεδίο γύρω από τον σωλήνα μέτρησης και υπολογίζει τον ρυθμό ροής μετρώντας την επαγόμενη ηλεκτροκινητική δύναμη που δημιουργείται όταν το αγώγιμο υγρό διέρχεται από το μαγνητικό πεδίο.

Εφαρμογή: Το διαιρούμενο ηλεκτρομαγνητικό ροόμετρο χρησιμοποιείται κυρίως για τη μέτρηση της ροής όγκου αγώγιμων υγρών και πολτών σε κλειστούς σωλήνες, συμπεριλαμβανομένων υψηλά διαβρωτικών υγρών όπως οξέα, αλκάλια και άλατα. Χρησιμοποιείται ευρέως σε βιομηχανίες όπως το πετρέλαιο, η χημική βιομηχανία, η μεταλλουργία, η κλωστοϋφαντουργία, τα τρόφιμα, τα φαρμακευτικά προϊόντα, η χαρτοποιία, καθώς και η προστασία του περιβάλλοντος, η δημοτική διαχείριση, οι κατασκευές εξοικονόμησης νερού κ.λπ.

Εφαρμογή:

Χημική βιομηχανία: Στη διαδικασία χημικής παραγωγής, είναι συχνά απαραίτητο να μετρηθεί η ροή διαφόρων διαβρωτικών υγρών όπως οξέα, αλκάλια και άλατα. Το διαιρούμενο ηλεκτρομαγνητικό ροόμετρο μπορεί να μετρήσει με ακρίβεια τη ροή αυτών των υγρών και τα ανθεκτικά στη διάβρωση ηλεκτρόδια και τα υλικά επένδυσης του μπορούν να εξασφαλίσουν μακροπρόθεσμη σταθερή λειτουργία.

Βιομηχανία χαρτοποιίας: Στη διαδικασία παραγωγής χαρτιού, είναι απαραίτητο να μετρηθεί η ροή υγρών όπως ο πολτός και τα χημικά παρασκευάσματα. Το διαιρούμενο ηλεκτρομαγνητικό ροόμετρο μπορεί να αντιμετωπίσει τις ίνες και τα σωματίδια σε αυτά τα υγρά, να παρέχει ακριβή δεδομένα ροής και να βοηθήσει στη βελτιστοποίηση της διαδικασίας κατασκευής χαρτιού.

Βιομηχανία επεξεργασίας νερού: Σε εγκαταστάσεις επεξεργασίας νερού, όπως μονάδες επεξεργασίας νερού και λυμάτων, χρησιμοποιούνται διαιρούμενα ηλεκτρομαγνητικά ροόμετρα για την παρακολούθηση της ροής του νερού εισόδου και εξόδου, βοηθούν στον έλεγχο της διαδικασίας επεξεργασίας νερού και διασφαλίζουν ότι η ποιότητα του νερού πληροί τα πρότυπα. Ταυτόχρονα, μπορεί επίσης να βοηθήσει στη βελτιστοποίηση της διαδικασίας επεξεργασίας του νερού και στη βελτίωση της αποτελεσματικότητας της επεξεργασίας.

Παράμετροι Προϊόντος:

| Επίπεδο ακρίβειας | Τύπος αγωγού: 0,5 επίπεδο, 1,0 επίπεδο |

| Σφάλμα επαναληψιμότητας | Τιμή μέτρησης ±0,1% |

| Μετρημένη μέση θερμοκρασία | Γενική επένδυση από καουτσούκ: -20~+60℃ Επένδυση από καουτσούκ υψηλής θερμοκρασίας: -20~+90℃ Επένδυση PTFE: -30~+100℃ Επένδυση PE υψηλής θερμοκρασίας: -30~+180°C |

| Ονομαστική πίεση εργασίας | Τύπος αγωγού: DN10-DN65:<2,5Mpa, DN80-DN150:<1,6Mpa, DN200-DN1200: <1,0Mpa |

| Ρεύμα εξόδου και αντίσταση φορτίου | 4~20mA πλήρως απομονωμένη αντίσταση φορτίου <750Ω, συχνότητα παλμών 0-1KHZ, φωτοηλεκτρική μόνωση εξωτερική τροφοδοσία OCT <35V, μέγιστο ρεύμα συλλέκτη 25mA όταν είναι ενεργοποιημένο |

| Υλικό ηλεκτροδίου | Ανοξείδωτο χάλυβα που περιέχει μολυβδαίνιο, τιτάνιο (Ti), ταντάλιο (Ta), Hastelloy (H), πλατίνα (Pt) ή άλλα ειδικά υλικά ηλεκτροδίων |

| Επίπεδο προστασίας | Υποβρύχιος τύπος: IP68, άλλοι τύποι IP65 |

| Παροχή ηλεκτρικού ρεύματος | 85~265V,45-63HZ |

| Μέθοδος σύνδεσης | Ο μετρητής ροής και οι σωληνώσεις συνδέονται με φλάντζες. |