Sensor medidor de condutividade

Sensor medidor de condutividade

- Accurate measurement: The use of advanced measurement technology and algorithms can achieve high-precision conductivity measurement. This is especially important for application scenarios that require precise control of liquid conductivity.

- Good stability: The stability of measurement results can be maintained during long-term use, reducing errors caused by sensor performance fluctuations.

- Signal processing technology: The use of advanced signal processing technology can effectively suppress the impact of interference signals on measurement results. Ensure the accuracy and reliability of measurement results in complex environments.

- Real-time monitoring: Fast response speed, able to monitor changes in liquid conductivity in real time. It is of great significance to industrial process control, environmental monitoring, etc.

Aplicativo:

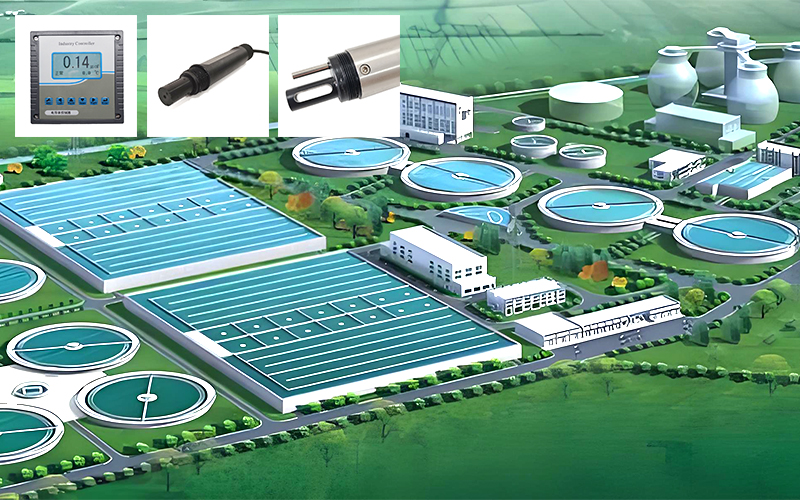

Industrial water monitoring: In industrial production, conductivity sensors are used to monitor the water quality of industrial water to ensure the stability of the production process and the quality of the product.

Sewage treatment plant: In a sewage treatment plant, conductivity meters are used to monitor changes in water quality during the treatment process to ensure that the effluent quality meets discharge standards.

Electroplating industry: During the electroplating process, the ion concentration in the water can be monitored in real time to ensure that the quality and thickness of the electroplating layer meet the requirements.

Parâmetros do produto:

| Working principle | Quadrupole electrode method |

| Faixa de medição | 0~200,000 μS/cm |

| Faixa | 20.00、200.0、2,000、20,000、200,000μS/cm automatic switching |

| Resolução | 0.01μS/cm ( depending on the range ) |

| Precisão de medição | < 1% |

| Tempo de resposta | < 15s |

| Communication interface | RS485,standard Modbus protocol |

| Ambiente de trabalho | 0~50 ℃ (no freezing),0~2 bar |

| Tensão de trabalho | 12V~24V DC |