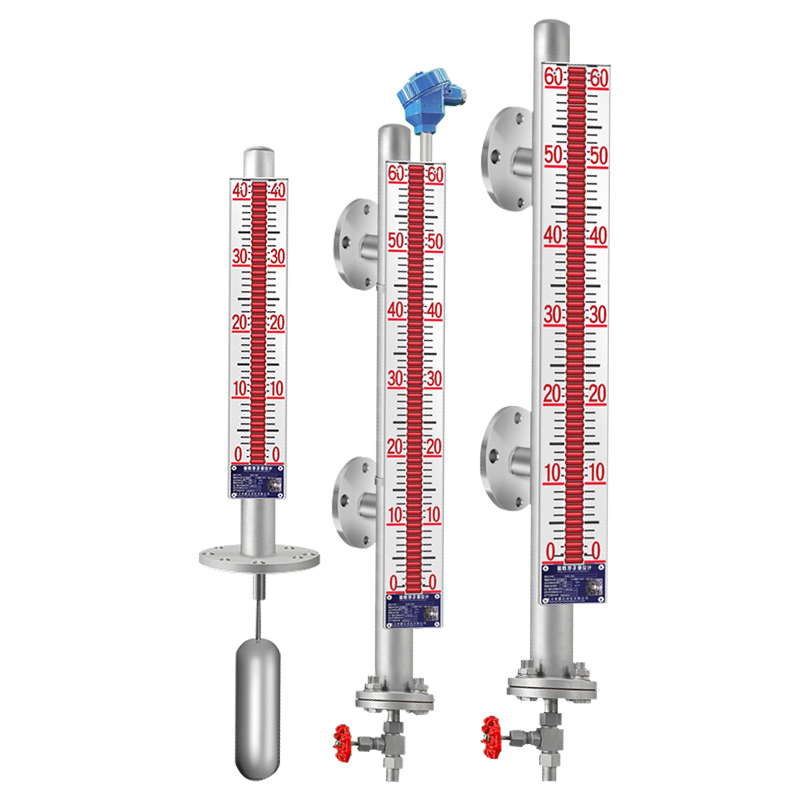

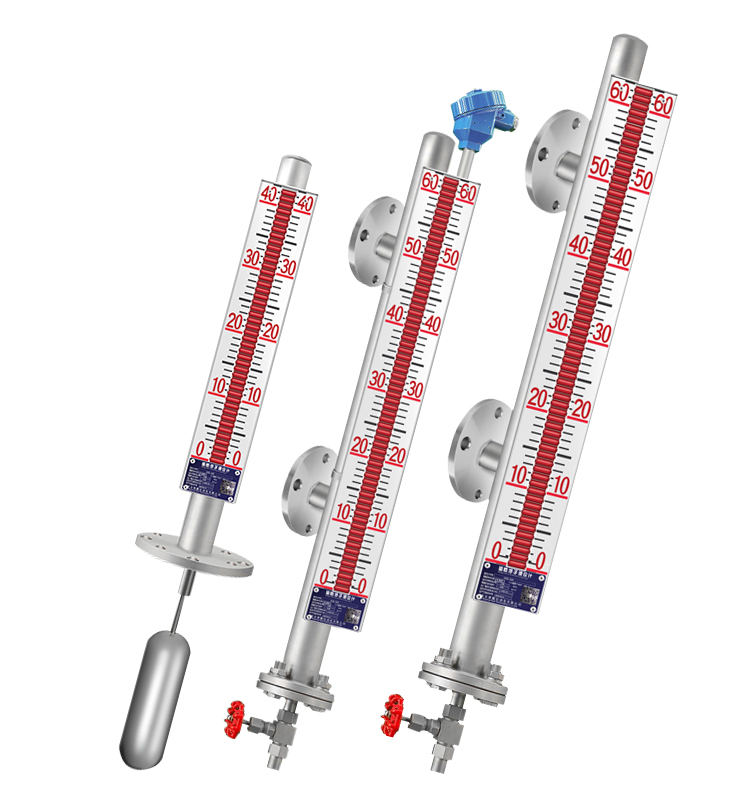

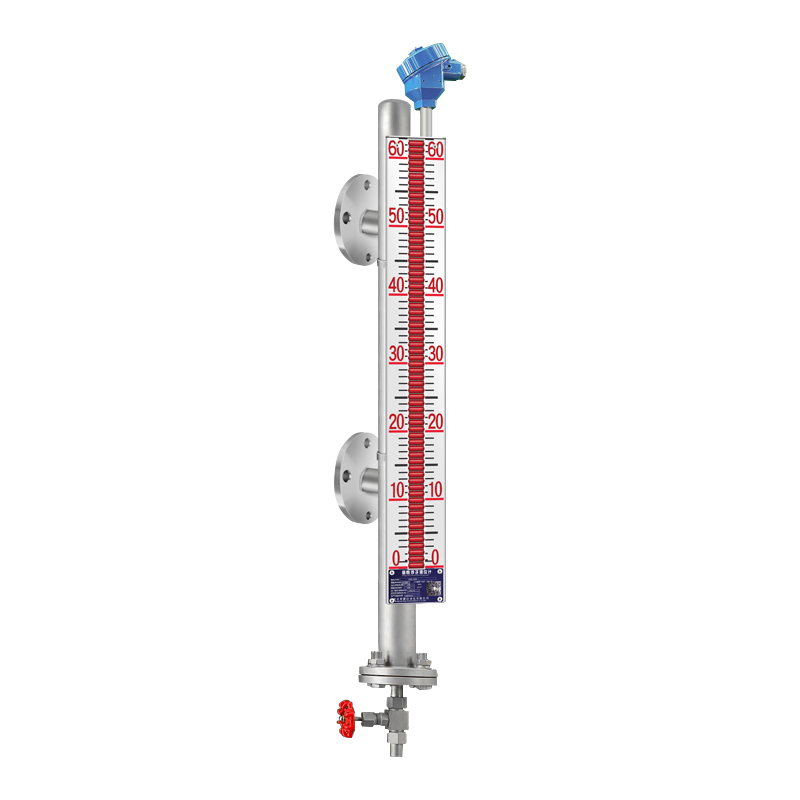

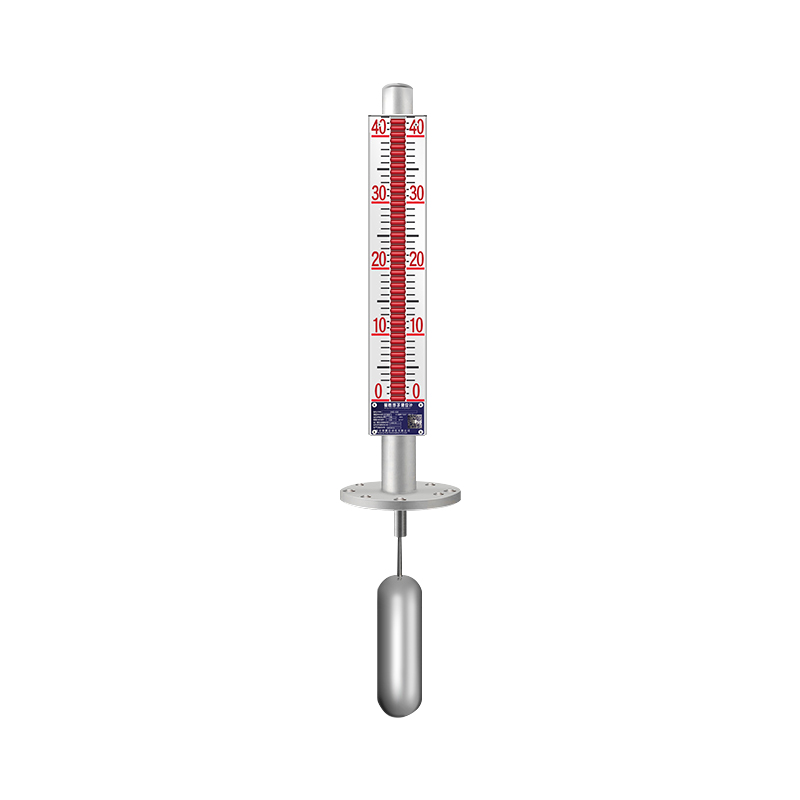

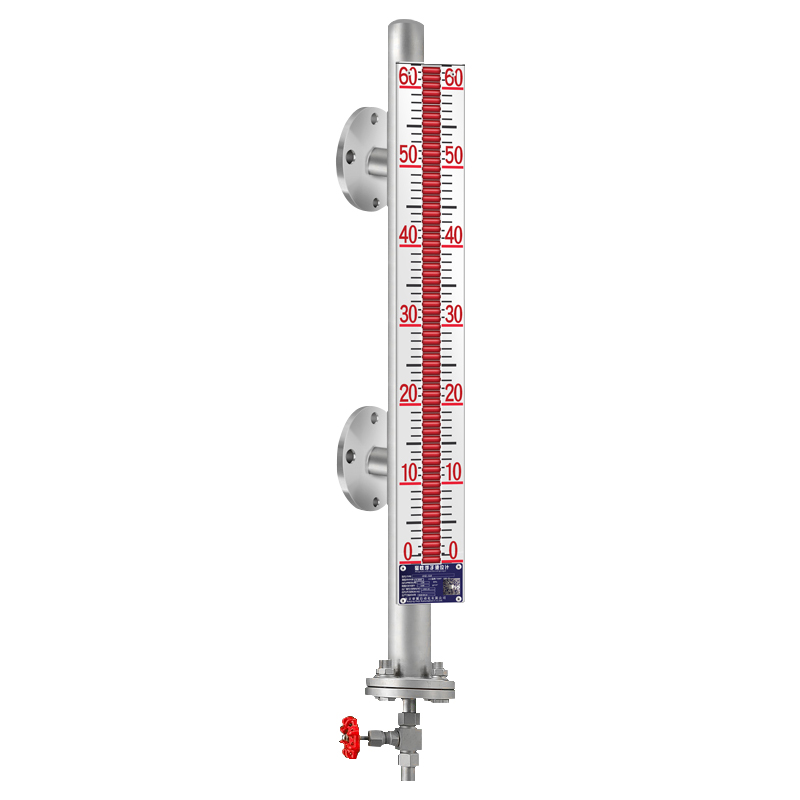

WH-ML016 Magnetic Level Transmitter

WH-ML016Magnetic Level Transmitter

- Simple structure, direct reading, easy operation, less maintenance;

- Measurement range is large, diameter range is wide;

- The level of corrosive medium can be measured;

- The remote alarm and control of liquid level can be realized;

- Support RS485 interface;

Introduction:

Magnetic level meter is used to measure the level of liquid in pressure vessel or open container. The transmitter can display the height of liquid level on the spot. With a liquid level control switch and alarm switch, the liquid level control, alarm and chain can be achieved. Equipped with built-in integrated liquid level transmitter, the liquid level (interface) signal can be converted into two-wire (4 ~ 20) MA standard signal to achieve remote detection and control of liquid level. Can be widely used in petroleum processing, municipal, food processing, chemical, water treatment, pharmaceutical, power, paper, metallurgy, ships, boilers and other fields.

Applications:

Chemical production: In the production of chemical industry, the liquid level detection of various reaction containers, as well as storage equipment such as tanks, barrels, and other storage equipment is an important application for magnetic level transmitter. By accurately measure the liquid level, it can avoid the waste of materials and the occurrence of safety accidents.

Pharmaceutical field: Various reaction containers and storage equipment in the pharmaceutical process require liquid level monitoring to ensure the correct execution of the production process and the stability of quality. The high precision and long service life of magnetic level gauge make it widely used in this field to ensure the quality and safety of drugs.

Petroleum industry: Diverse and complicated liquid measurement demand in tanks and pipelines in the petroleum industry, and the transmitter can meet these needs. The gauge can provide high -precision liquid level measurement, thereby improving the use efficiency of the storage tank. In addition, it can also be used in the liquid level control during oil refining to ensure the normal production process.

Parameters:

Performance parameters:

| Measuring variable | liquid level |

| Measuring Range | (0~6)m Other range can be customized, up to 20m |

| Accuracy | ±20mm |

| Temperature Drift | <540ppm/℃ |

| Protection degree | IP65 |

Output parameters:

| Variable output | 2-wire (4~20) mA, current output accuracy 0.5% FS |

| Communication Output | RS485, Modbus RTU protocol |

| Limit switch output | double set/four set SPST reed switch |

Power parameters:

| Power supply | 24VDC |

| Power consumption | Max 0.3W |

| Electrical interface | M20*1.5 cable plug |

Process condition parameters:

| Medium density | (0.45~2.0)g/cm3 |

| Medium viscosity | ≤0.4Pa·s |

| Medium temperature | (-40~80)℃/(0~150)℃/(0~350)℃ |

| Process pressure | (-0.1~16)MPa |

Environmental parameters:

| Working Environment | Temperature:(-20~80)℃ Humidity:0~80% |

| Storage environment | Temperature:(-80~120)℃ Humidity: 0~85% |